The Cornerstone of Modern Logistics: Wheeled Plastic Crates

Their Integration in Logistics and Warehousing

In today's rapidly evolving supply chain and logistics ecosystem, efficiency, speed, and workplace safety have become the most critical elements of operational success. With the rise of e-commerce, the secure and rapid transport of products from storage areas to shipping points and then to shelves is of vital importance for businesses in every sector. These increasing demands have necessitated the replacement of traditional transport methods with more flexible, durable, and ergonomic solutions. At the center of this transformation are wheeled plastic crates, which serve as a modular system combining the durability and functionality of plastic crates with the mobility of wheeled transport platforms (dolly). These systems are more than just transport equipment; they offer integrated solutions that simplify modern workflows, optimize labor, and reduce operational costs.

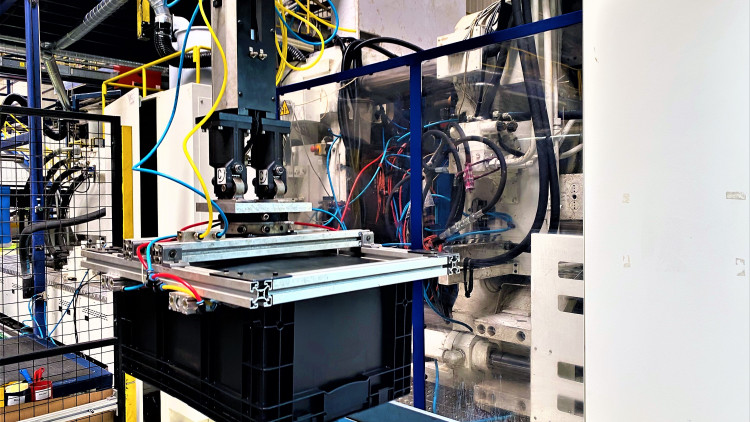

Benoplast, founded in 2008 to meet these modern needs, has made it its mission to make a difference with sustainable and reusable product systems. The company operates with a vision of becoming a leading brand in the global market for transport and storage solutions by combining advanced technology with expert human resources. Its rapid growth and innovation-oriented approach since its early years were reinforced by the establishment of the Plastiko recycling facility in 2008, solidifying its commitment to sustainability. Today, Benoplast stands as a strong player in the international market, ranking among Europe's leading producers, exporting to more than 70 countries, and employing over 700 people.

This comprehensive report aims to detail the key advantages, sectoral applications, quality standards, and innovation approach of Benoplast's wheeled plastic crate solutions. The goal is to demonstrate that these products are not merely equipment but strategic investments that increase operational efficiency, reduce costs, and support environmental responsibility.

Key Advantages and Benefits of Wheeled Plastic Crates

Wheeled plastic crates offer a holistic approach to the challenges faced in storage and logistics processes. These solutions overcome the limitations of traditional transport methods, providing businesses with versatile and tangible benefits.

Operational Efficiency and Ergonomics: Reducing Labor and Gaining Speed

One of the most significant benefits of wheeled plastic crates is the increase in operational efficiency they provide. While traditional crates can lead to fatigue and workplace accidents when carried by human power, wheeled platforms (dolly) eliminate this burden. The combination of lightweight and durable plastic crates with wheeled transport vehicles significantly reduces labor by allowing heavy loads to be moved with ease. For example, Benoplast's wheeled crate solutions accelerate dynamic transport processes, facilitating material flow in warehouse, factory, and retail environments.

Maximum Durability and Product Safety: High Capacity and Impact Protection

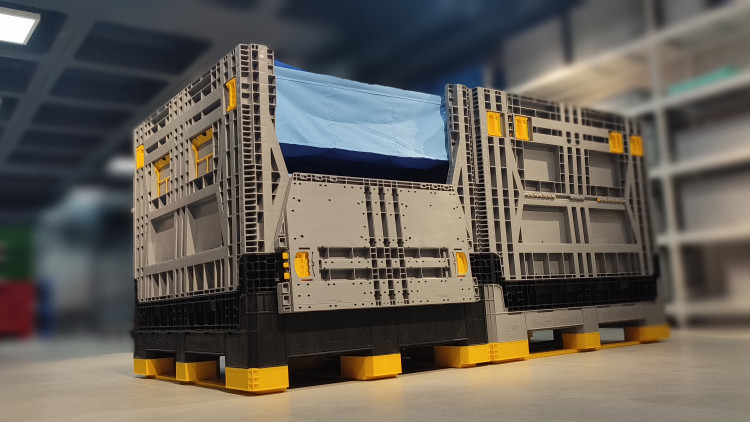

The high-quality raw materials used in the production of plastic crates maximize product safety. Benoplast typically prefers durable materials such as polypropylene copolymer (PPC) and polyethylene (PE) for its products. These materials provide a strong structure against challenging industrial conditions and impacts, while also being able to carry heavy loads without issue. The fact that a large wheeled plastic container can carry a dynamic capacity of 400 kg and a static capacity of 600 kg demonstrates how reliable these products are.

Hygienic and Environmentally Friendly Structure: Solutions from Food to Pharmaceutical Sectors

The smooth surfaces of plastic crates prevent the accumulation of dirt and microbes, offering easy cleaning and superior hygiene standards. This feature is indispensable, especially for sensitive sectors such as food, agriculture, and pharmaceuticals. The use of food-grade raw materials allows Benoplast products to be used safely for the transport and storage of fruits, vegetables, meat, and dairy products.

Flexibility and Customization Options: Solutions for Different Sectors

One of the most important values of wheeled plastic crates is their ability to be customized according to a customer's specific needs. Benoplast can add various branding and labeling applications to its products, such as screen printing, laser printing, sequential numbering, hot stamping, and PVC/plastic kanban pockets. These features simplify inventory management and tracking processes for companies.

Sector-Based Wheeled Crate Solutions

Wheeled plastic crates offer solutions tailored to the unique needs of a wide range of sectors.

Logistics and E-Commerce: The Secret to Fast and Secure Shipping

The demand for fast and flexible delivery brought by e-commerce has revolutionized logistics processes. Wheeled crates accelerate picking and order consolidation processes in warehouses, ensuring that products are delivered to the end consumer in a trackable and complete manner via road, air, or sea. Benoplast proves its expertise in this area through collaborations with leading brands such as Turkish Cargo, Trendyol, İsteGelsin, Getir, and A101 Kapıda.

Automotive and Industry: Durable Structures for Heavy Loads

The automotive sector has extremely strict standards for the safe transport and storage of parts and components. Benoplast's Industrial Crates and VDA-KLT crates are specifically designed to meet the demanding requirements of the automotive industry. Thanks to their reinforced structures and heavy load capacity, these crates enable the secure transfer of a wide range of products, from engine parts to electronic components.

Food and Agriculture: Hygienic Transport of Fresh Products

Food safety is the top priority for the agriculture and food sectors. Benoplast's food-grade, perforated, and lidded crates allow fresh fruits and vegetables to be transported with proper air circulation, while lidded models protect products from external factors, ensuring hygienic conditions are maintained. These solutions help products preserve their freshness from the field to the market shelf and offer an ideal option for the transport of various products such as olives, figs, and oranges.

Retail and Chain Markets: Facilitating In-Store Flow

Chain markets and the retail sector constantly need to optimize their warehouse and in-store logistics processes. Wheeled crates enable products to be moved from the back store to the sales shelves quickly and easily, significantly speeding up stock replenishment processes. Additionally, Benoplast's collapsible plastic crates save storage space when not in use, providing a significant cost advantage, especially for stores with limited space.

Discover Benoplast's Quality and Innovation

Benoplast demonstrates its commitment to quality and an innovative approach in every aspect of its corporate structure.

Sustainable Approach: Benoplast's Recycling Mission

Benoplast's commitment to the "circular economy" model is at the core of its production processes. The company's sub-brands such as Plastiko and TRENTO create an integrated ecosystem that extends from production to leasing and recycling. This structure not only acts with a sense of responsibility for a sustainable future but also creates added value by offering reusable and environmentally friendly solutions to customers.

Product-Specific Design and a Wide Product Range

Benoplast stands out with its "product-specific design" approach tailored to the specific needs of various sectors. This approach aims to collaborate with customers to develop the most suitable and functional solutions for them, rather than simply offering standard products.

The table below shows the technical specifications of some of the standard models offered by Benoplast for wheeled transport platforms (dolly).

International Quality Standards: Our ISO Certificates and Reliable Production

Quality certifications play a critical role in Benoplast's gaining assurance and reputation in the international market. The company guarantees the reliability and quality of its production and management processes with the following ISO certificates:

Our Achievements Strengthened by Our Story: Looking to the Future with Confidence

Benoplast's growth since its establishment in 2005 is a reflection of its strategic vision. The opening of factories in different locations like Yalova and Kütahya, regional directorates, and sales offices in Germany and the USA are evidence that the company has achieved its goal of expanding its global footprint. This growth story has positioned Benoplast as a leader in the industry, resulting from its focus on innovation, quality, and customer satisfaction.

Things to Consider When Choosing the Right Wheeled Plastic Crate

Choosing the right wheeled plastic crate is a critical decision for a business to achieve its operational goals. The main factors to consider in this selection are:

Material and Durability: PPC, PE, and ESD Features

The appropriate raw material should be chosen based on the sector and the load the crate will carry. Durable materials like PPC (Polypropylene Copolymer) are ideal for heavy loads and impacts. For sensitive electronic products,ESD (Electrostatic Discharge)-featured crates should be preferred, as they safely protect products.

Size and Capacity: The Right Dimensions for Your Needs

Correct size and carrying capacity are vital for optimizing logistics costs and warehouse space. Crate selection should be made according to the volume, weight, and stacking requirements of the products to be transported. Understanding technical terms such as static carrying capacity (the weight that the base of stacked crates can support) and dynamic carrying capacity (the maximum weight that can be applied to a moving crate) helps in identifying the right product.

Extra Features: Braked Wheels, RFID Tags, and Lid Options

Additional features that can be added to crates and transport platforms can significantly increase the product's functionality.

Braked wheels provide safety on inclined surfaces or in places where the crate needs to remain stationary, while RFID tags enable the automatic tracking of the crate and its contents. Additionally,lockable or sealable lids enhance the security of products throughout the logistics chain.

Conclusion: The Future of Logistics is Being Shaped Today

Wheeled plastic crates are not just a means of transport for modern businesses but a strategic investment on the path to operational excellence. These solutions fundamentally transform logistics and storage processes by reducing labor, increasing product safety, raising hygiene standards, and supporting environmental sustainability.

Benoplast is positioned as a pioneer in this field with its deep expertise, innovative product range, and commitment to international quality standards. The company designs each of its products not just as packaging, but as a solution to the challenges its customers face. Wheeled plastic crates make logistics and storage processes smarter, safer, and more sustainable, shaping the future supply chain model today.