How is Plastic Crate Manufacturing Done?

September 25, 2023

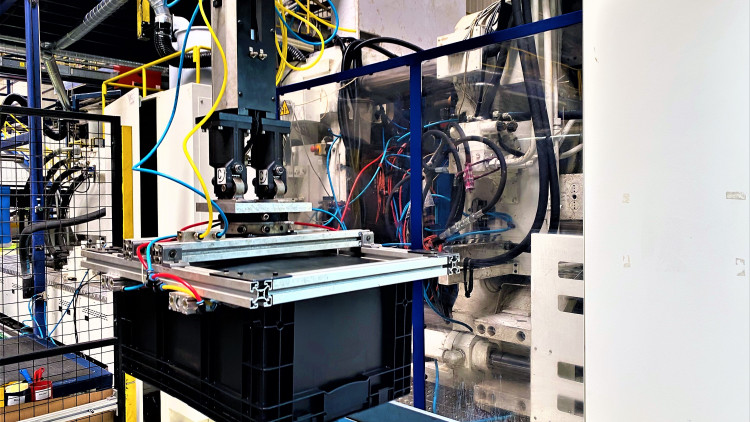

Plastic case manufacturing is done using injection molding technique. After the plastic is melted and turned into liquid, it takes shape by injecting it into steel molds. After the mold cools, the plastic container takes the exact shape of the mold and solidifies. In this production process, types of raw materials such as polyethylene (PE) or polypropylene (PPC) are usually used. Plastic containers can be used successfully in various processes such as transportation, storage and stacking of products.

It is among the preferred products in many industries, including the chemical, automotive, logistics, electronics and textile sectors. Especially when first-class quality raw materials are used, plastic containers become suitable for food contact. They are frequently preferred for transportation and storage of products in food industries such as seafood, agricultural products, dairy, bakery products and meat.

Plastic Case Production

Thanks to the structure of these containers, they can be easily stacked on top of each other and nested within each other. Additionally, open and closed handles help users carry the products comfortably for work safety. With these features, plastic case manufacturing contributes to carrying out work more efficiently and safely in various sectors. Plastic case manufacturing is used in various sectors to greatly facilitate business processes.

It has a wide range of uses to make activities such as transportation, stacking, sorting, transportation and logistics more efficient. Thanks to their lightweight design, plastic cases increase the circulation speed of the items and make them extremely easy to use. At the same time, since air and liquid permeability features can be designed optionally, it helps to preserve the products used in special conditions.

Plastic crates are especially preferred for food storage and transportation as they are produced in accordance with hygienic standards. Since it is made of a solid and durable material, it offers high impact resistance and long-lasting resistance to intensive use. Especially the closed bottom base and ventilated wall design offer an ideal solution for the logistics of delicate products that need to be ventilated, such as fruits and vegetables.

Information About Plastic Case Manufacturing

These features provided by plastic cases contribute to a more orderly, efficient and safe execution of business processes. Plastic case manufacturing has customization opportunities and can be tailored to customers' personal preferences using methods such as kanban pockets and screen printing. Additionally, users can easily track plastic cases by adding RFID tags.

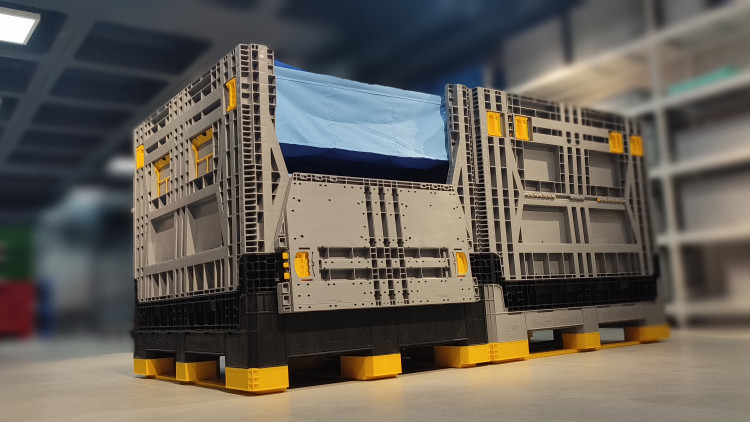

Antistatic cases with electrostatic properties (ESD) protect the products they contain. Plastic crates have an environmentally friendly structure and can also be recycled and reused. Plastic cases, which can be produced in different sizes, may include measurements and dimensions such as 30x50, 40x60, 40x40, 30x40, 40x80. In addition, thanks to its foldable features, it saves space for companies in terms of logistics. Plastic crates, like other plastic products, are produced using plastic raw material products.